The Transformative Power of **3D Design and Printing**: A Gateway to Innovation and Business Success

Understanding the Basics of 3D Printing Technology

In recent years, the 3D printing industry has experienced exponential growth, serving as a pivotal component in various sectors, from manufacturing to healthcare. The cornerstone of this transformation is the integration of 3D design and printing, a combination that enhances product development, reduces costs, and accelerates time-to-market.

How 3D Design and Printing Work Together

The process of 3D printing begins with 3D design, where digital models are created using computer-aided design (CAD) software. These models are then converted into a format suitable for printing, commonly known as STL (stereolithography). The printer interprets this data to construct a physical object layer by layer. This technology facilitates a wide range of materials, including plastics, metals, and even bio-materials.

Key Stages in 3D Design and Printing

- Conceptualization: Initial ideas are transformed into digital drawings.

- Modeling: CAD software is used to build 3D models with intricate details.

- Slicing: The model is sliced into layers, creating instructions for the printer.

- Printing: The 3D printer constructs the object layer by layer.

- Post-Processing: Finishing touches are applied to improve appearance and functionality.

The Business Advantages of ECD.vn 3D Design and Printing

Investing in ECD.vn 3D design and printing can provide businesses with significant competitive advantages. Here are some key benefits:

1. Cost-Efficiency

3D printing minimizes material waste and lowers production costs. Businesses can create prototypes and end-use products without the significant costs associated with traditional manufacturing processes.

2. Rapid Prototyping

One of the most powerful applications of 3D printing is rapid prototyping. Businesses can quickly iterate designs and bring products to market faster. This speed fosters innovation and allows companies to respond to market demands and customer feedback efficiently.

3. Customization and Personalization

3D printing enables the creation of customized products tailored to specific customer needs. This personal touch can significantly enhance customer satisfaction and build brand loyalty.

4. Complex Geometries

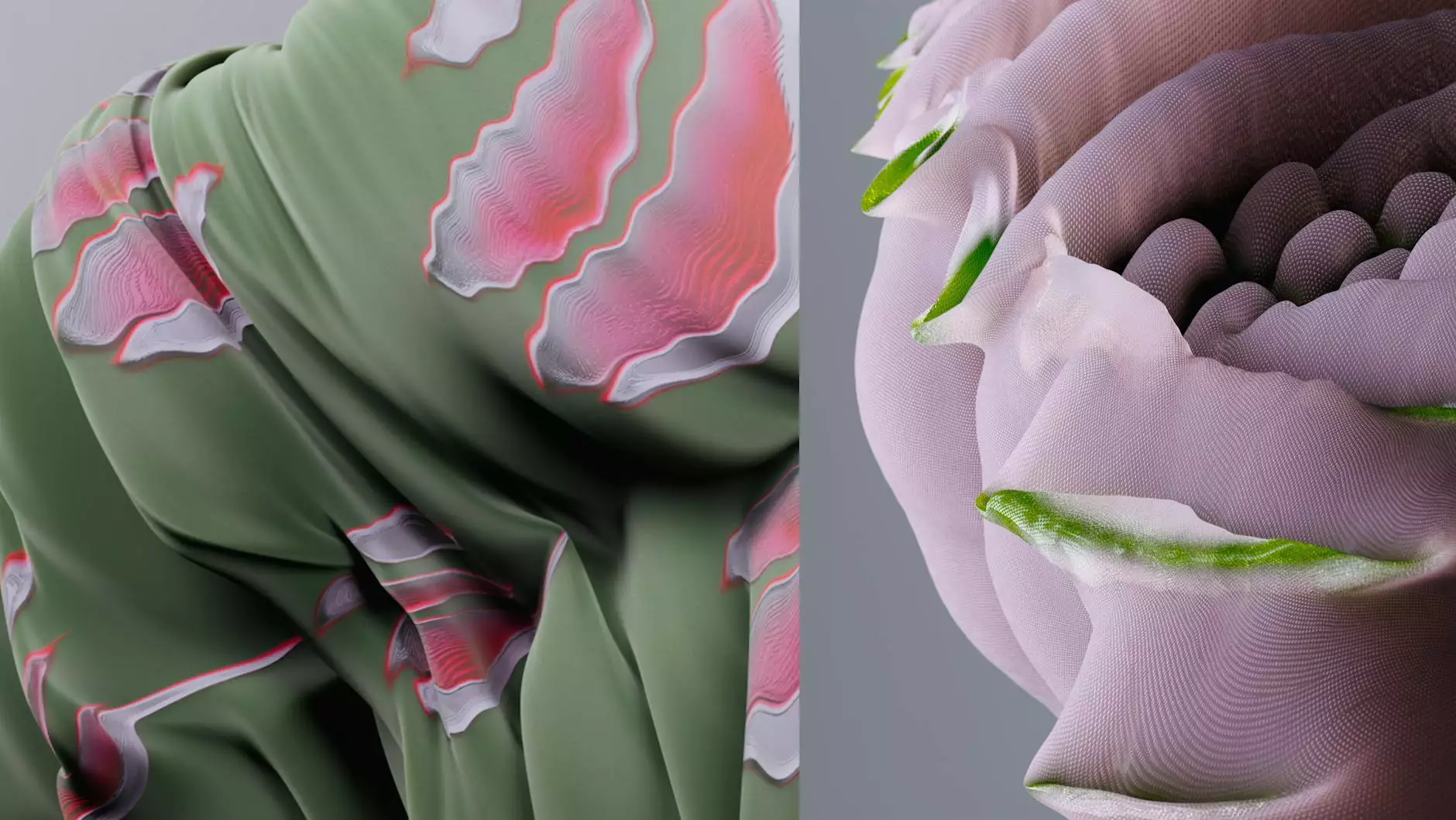

Unlike traditional manufacturing processes, 3D printing allows for the production of complex geometries and intricate designs that would be impossible or cost-prohibitive to create using conventional methods.

5. Sustainable Innovation

As sustainability becomes increasingly crucial in business, 3D printing offers a path toward greener practices. By optimizing resource usage and reducing waste, companies can lower their environmental impact.

Industry Applications of 3D Design and Printing

The capabilities of 3D design and printing span a vast array of industries. Here are some notable fields where this technology is making significant strides:

1. Healthcare

In the healthcare industry, 3D printing is being utilized to create prosthetics, dental implants, and even bioprinted tissues. These customized solutions improve patient outcomes and streamline surgical procedures.

2. Aerospace and Automotive

Both the aerospace and automotive sectors benefit from the lightweight and durable parts produced through 3D printing. This technology accelerates the prototyping phase, allowing for innovative designs that enhance fuel efficiency and performance.

3. Consumer Goods

From jewelry to footwear, 3D printing allows designers to create unique products that reflect individual styles. The ability to produce limited runs or tailored items meets the growing demand for personalization in consumer goods.

4. Architecture and Construction

In architecture, 3D printing is utilized for creating models and even constructing entire buildings. This innovation not only saves time and labor but also allows for creative designs that challenge traditional architecture norms.

The Future of ECD.vn 3D Design and Printing

The future of 3D design and printing is bright and full of possibilities. As technology continues to evolve, we can expect various trends to emerge:

1. Increased Material Variety

Advancements in material science will lead to an expanded selection of materials suitable for 3D printing, including biodegradable and recycled materials, enhancing sustainability.

2. Integration with Other Technologies

Combining 3D printing with technologies like artificial intelligence, the Internet of Things (IoT), and augmented reality will create new capabilities and improvements in design and production processes.

3. Full-Scale Production

As technology progresses, 3D printing is expected to shift from prototyping to full-scale production, allowing for greater flexibility in manufacturing and supply chains.

4. Fabrication Tolerance and Speed

With every innovation in 3D printing technology, we will see improvements in precision, speed, and the overall finish of printed products, bringing them closer to traditional manufacturing standards.

Conclusion: Embrace the Potential of ECD.vn 3D Design and Printing

In conclusion, ECD.vn 3D design and printing stands at the forefront of a technological revolution that has the potential to transform how businesses operate. By embracing this innovative technology, companies can enhance efficiency, foster creativity, and meet the evolving needs of their customers. As the landscape continues to evolve, staying ahead of the curve with 3D design and printing will become increasingly crucial in maintaining a competitive edge in the market.

Investing in 3D design and printing is not just a choice—it's a strategy for future-proofing your business. Explore the opportunities today, and witness how ECD.vn can redefine what's possible in your industry.